Radiation Curing

Understanding the curing of resins and inks by radiation

The curing of resins and inks by light energy can be traced back many centuries to Ancient Egypt when resin-soaked mummification wrappings were cured by sunlight. In 1815, the world saw the first photoengraved printing plate, and for the following 150 years many photochemical reactions have made their marks on history, but a commercial radiation-curing process did not evolve until the 1960s.

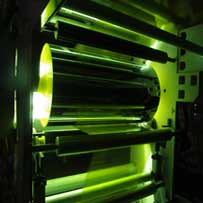

Radiation curing is the technology of utilizing short wavelength ultraviolet (UV) light, or high-energy electrons from electron-beam (EB) sources, to cure (cross-link) special reactive coatings, varnishes, inks and adhesive formulations. These products are formulated using selective materials that react to UV and EB energy forms to yield very specific performance properties. Characteristically, both processes cause liquid coatings, varnishes, inks and adhesives to change into solids virtually instantly. Curing is very fast and cool in relative terms, which allows applications to heat sensitive substrates. Once cross-linked, properly cured products exhibit both high physical- and chemical-resistant properties.

The UV process utilizes photons generated by high-intensity UV light to initiate the free-radial cross-linking of acrylate oligomers and prepolymers. Ultraviolet light is electromagnetic radiation that has a wavelength that falls to the shorter wavelength side of visible light, while infrared (IR) falls adjacent to the longer wavelength side.

The features, advantages and benefits of radiation curing

Normally, conventional thermally cured coatings are composed of a resinous binder, pigments and fillers, and diluent solvents. After application to the substrate, heat is applied, driving off the solvents and curing the coating film. The evaporated solvents are generally flammable, and must be considered pollutants. These solvent emissions require the use of even more energy to be burned or “scrubbed” and recovered by distillation. A great deal of expense in involved in heating the coating, substrate, and solvent. It is an inefficient, uncomfortable and messy process.

In radiation curing the resin binder is replaced by a formulation of liquid monomers and oligomers, into which the pigment can be dispersed, generally without the need for either solvent or water. The coating is completely reactive and the amount, or thickness, that is laid down wet is, essentially, the same as the thickness after curing.